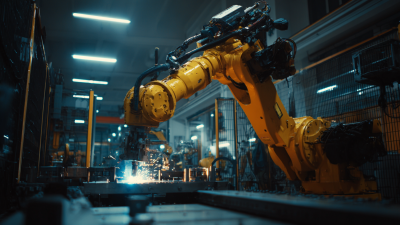

Robotic welding is transforming the manufacturing landscape, equipping skilled workers with the necessary expertise to thrive in an increasingly automated industry. According to industry expert Dr. Emily Carter, a leading figure in robotic automation, “Continuous learning through specialized training, such as robotic welding classes, is crucial for professionals aiming to stay competitive in this dynamic field.” As the demand for precision and efficiency in welding grows, enrolling in the best robotic welding classes becomes an essential step for those looking to enhance their skills.

Robotic welding is transforming the manufacturing landscape, equipping skilled workers with the necessary expertise to thrive in an increasingly automated industry. According to industry expert Dr. Emily Carter, a leading figure in robotic automation, “Continuous learning through specialized training, such as robotic welding classes, is crucial for professionals aiming to stay competitive in this dynamic field.” As the demand for precision and efficiency in welding grows, enrolling in the best robotic welding classes becomes an essential step for those looking to enhance their skills.

In 2023, numerous options are available for aspiring welders and experienced professionals alike to develop their craft. From hands-on workshops to extensive certification programs, these classes are designed to provide an in-depth understanding of robotic welding technologies and their practical applications. With advancements in automation, the knowledge gained from these educational opportunities not only improves individual capabilities but also boosts overall productivity within the industry.

As we explore the top robotic welding classes for 2025, it’s important to recognize the profound impact that quality training has on both career prospects and the future of welding technology. Whether you're a beginner or looking to refine your skills, these classes pave the way for success in an era defined by innovation.

As we delve into the top trends in robotic welding for 2023 and beyond, the burgeoning robotic automation market demonstrates significant evolution. With the global welding market projected to grow from $24.73 billion in 2023 to $34.18 billion by 2030, the integration of collaborative robots is revolutionizing traditional welding processes. These advanced systems enhance efficiency, reduce labor costs, and improve the precision of welds, making them indispensable in modern manufacturing.

Moreover, the demand for skilled workers trained in robotic welding is more critical than ever as industries seek to adapt to the rapid technological advancements. Educational institutions are responding by offering comprehensive robotic welding classes, equipping professionals with the necessary skills to operate and maintain these complex machines. With the rise of automated welding technologies, it's clear that those who invest in their skills will be at the forefront of the industry's transformation. As the market evolves, staying ahead through education and training is key to leveraging the full potential of robotic welding.

Robotic welding classes offer a unique opportunity to master essential skills that can enhance your career in manufacturing and automation. One fundamental skill taught in these classes is programming robotic welders. Trainees learn how to write and troubleshoot code, ensuring the robot completes precise welds according to project specifications. Understanding the various welding techniques, such as MIG and TIG welding, is also crucial, as each method has specific applications and advantages in different materials and environments.

Robotic welding classes offer a unique opportunity to master essential skills that can enhance your career in manufacturing and automation. One fundamental skill taught in these classes is programming robotic welders. Trainees learn how to write and troubleshoot code, ensuring the robot completes precise welds according to project specifications. Understanding the various welding techniques, such as MIG and TIG welding, is also crucial, as each method has specific applications and advantages in different materials and environments.

In addition to technical skills, students develop an eye for detail, learning to assess weld quality and make necessary adjustments. Safety protocols are heavily emphasized, teaching students how to work effectively within an industrial environment while minimizing risks. Furthermore, classes often incorporate hands-on practice, allowing students to apply theoretical knowledge in real-world scenarios, fostering problem-solving abilities and teamwork skills. By enhancing these competencies, individuals can position themselves as valuable assets in a competitive job market.

When considering robotic welding training, one of the primary decisions is whether to pursue

online or in-person classes.

Online training offers flexibility and convenience, allowing learners to study at their own pace

without the constraints of a fixed schedule. This mode is particularly beneficial for those balancing

work commitments or family responsibilities, as participants can access materials anytime, anywhere,

fostering a self-directed learning environment.

When considering robotic welding training, one of the primary decisions is whether to pursue

online or in-person classes.

Online training offers flexibility and convenience, allowing learners to study at their own pace

without the constraints of a fixed schedule. This mode is particularly beneficial for those balancing

work commitments or family responsibilities, as participants can access materials anytime, anywhere,

fostering a self-directed learning environment.

On the other hand, in-person classes provide hands-on experience that is often crucial in mastering

complex welding techniques. With direct interaction with instructors, learners can receive immediate

feedback and engage in practical exercises that simulate real-world welding scenarios. This method

sharpens both technical skills and problem-solving abilities,

which are essential in the robotics field.

Tips:

When choosing between online and in-person training, consider your learning style and schedule.

If possible, take advantage of hybrid models that combine both formats for a more rounded experience.

Be sure to research the credentials of trainers and institutions,

as well as any available certifications, to ensure the quality of education you receive will benefit your career.

In the rapidly evolving field of robotic welding, obtaining the right certifications is crucial for professionals looking to enhance their skills and career prospects. Key certifications such as the Certified Robotic Arc Technician (CRAT) and the Certified Welding Inspector (CWI) are designed to equip individuals with the necessary competencies to operate advanced welding technologies effectively. These certifications not only validate a welder's expertise but also signify their commitment to adhering to industry standards and safety protocols.

Additionally, specialized programs like the National Center for Welding Education and Training (Weld-Ed) initiatives offer comprehensive training that combines theoretical knowledge with hands-on experience. This blend is vital as it prepares professionals to tackle real-world challenges in robotic welding environments. Pursuing these certifications and courses can significantly boost a welder's confidence and make them more competitive in the job market, paving the way for greater opportunities and advancements in their welding careers.

As industries increasingly adopt automation technologies, the demand for professionals skilled in robotic welding is on the rise. The integration of robotic systems in manufacturing not only boosts productivity but also enhances precision and reduces human error. Consequently, individuals proficient in robotic welding are finding themselves in a favorable position in the job market. With an array of industries, from automotive to aerospace, harnessing the power of robotic welding, job opportunities are expanding rapidly for those equipped with the necessary skills.

Furthermore, as companies seek to remain competitive, they are investing heavily in automation and advanced manufacturing processes. This trend highlights the importance of ongoing education and training in robotic welding. With courses designed to provide hands-on experience and theoretical knowledge, aspiring welders can enhance their expertise and adapt to the evolving technological landscape. As the future unfolds, those who invest in developing their skills in robotic welding will likely find themselves at the forefront of this growing field, ready to take on new challenges and contribute to innovative manufacturing solutions.

| Class Title | Duration | Location | Level | Certification |

|---|---|---|---|---|

| Advanced Robotic Welding Techniques | 6 weeks | Online | Advanced | Yes |

| Introduction to Robotic Welding | 4 weeks | Local Campus | Beginner | No |

| Robotic Welding for Manufacturing | 8 weeks | Hybrid | Intermediate | Yes |

| Hands-On Robotic Welding Mastery | 3 months | Local Campus | Advanced | Yes |

| Programming Robotic Welders | 5 weeks | Online | Intermediate | Yes |

| Safety in Robotic Welding | 2 weeks | Online | All Levels | Yes |

| Welding Robotics Bootcamp | 10 weeks | Local Campus | Beginner to Advanced | Yes |

| Robotics and Automation in Welding | 6 weeks | Online | Intermediate | Yes |

| Laser and Robotic Welding Integration | 4 weeks | Local Campus | Advanced | No |

| Certification in Robotic Welding | 3 weeks | Online | All Levels | Yes |

Contact Us

Pemamek Ltd