In the world of welding fabrication, mastering techniques is vital for successful projects. According to John Smith, a renowned expert in welding fabrication, "Precision and creativity are key to transforming metal into art." This statement captures the essence of what makes welding fabrication both a skill and an art form.

Every project presents unique challenges. Effective techniques can significantly impact the quality of the final product. For instance, using proper joint designs can enhance strength while ensuring aesthetics. However, it’s easy to overlook the importance of preparation. Failing to plan can lead to mistakes that compromise your work.

Moreover, experimentation is part of the journey. Some methods may not yield the desired results initially. Learning from these experiences is crucial for growth. It’s essential to remain adaptable and open-minded. The evolving nature of welding fabrication pushes craftsmen to constantly refine their skills and techniques.

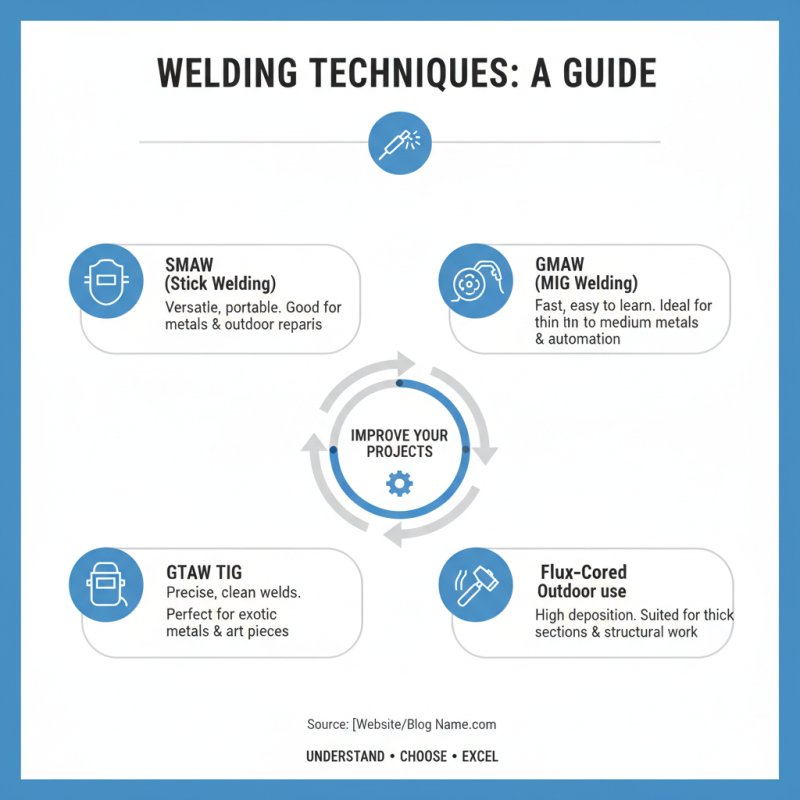

Welding fabrication techniques play a crucial role in metalworking. Understanding how to effectively use these methods can significantly enhance the quality of your projects. According to the American Welding Society, proper welding techniques can improve metal strength by up to 50%. This emphasizes the need for skillful execution and a deep knowledge of various techniques.

Different fabrication methods can yield different results. For example, MIG welding is often praised for its speed, but it may compromise on strength. Stick welding, on the other hand, often requires a high level of precision. Studies show that improper techniques can lead to defects, costing companies about $2.5 billion annually in repairs and downtime. This highlights the importance of mastering the right approach.

Welders frequently face challenges when it comes to material selection and environmental conditions. For instance, the presence of moisture can severely affect weld quality. Many skilled welders reflect on their past mistakes to avoid repeating them. Continuous learning and practice are vital for honing these important skills, ultimately leading to improved project outcomes.

| Technique | Description | Applications | Advantages |

|---|---|---|---|

| MIG Welding | Metal Inert Gas welding uses a continuous wire feed to create a weld. | Automotive repair, manufacturing, and metal fabrication. | Fast and versatile, easy to learn. |

| TIG Welding | Tungsten Inert Gas welding provides precise control with a non-consumable tungsten electrode. | Aerospace, piping, and food-grade applications. | Produces high-quality, precise welds. |

| Stick Welding | Shielded Metal Arc Welding uses a consumable electrode coated in flux. | Construction, outdoor work, and repair jobs. | Effective in windy conditions and on dirty materials. |

| Flux-Cored Welding | Similar to MIG, but uses a tubular wire filled with flux. | Heavy fabrication, shipbuilding, and bridge construction. | Good for thick materials and outdoor conditions. |

| Plasma Cutting | Uses an electrical arc to melt and cut through metal. | Metal art, fabrication, and repairs. | High precision and speed, capable of cutting various materials. |

| Oxy-Acetylene Welding | Uses a flame produced by burning acetylene and oxygen. | Metal repairs, sculpture, and brazing. | Versatile and can weld, braze, or cut metals. |

| Submerged Arc Welding | Arc formed between a bare wire electrode and the workpiece submerged under a blanket of granular fusible flux. | Heavy plate welding in shipbuilding and structural applications. | High deposition rate and deep penetration. |

| Resistance Welding | Uses electric current to heat and bond metals at the joint. | Automotive assembly and manufacturing. | Fast and energy efficient, minimal distortion. |

| GTAW Welding | Gas Tungsten Arc Welding specializes in welding thin materials. | Industries requiring high integrity joints. | Excellent welding properties and clean appearance. |

Welding techniques are essential in various industries. Each technique serves a specific purpose. Understanding these techniques can help improve your projects.

Arc welding is common in construction. It uses an electric arc to create heat and fuse metals. This method is effective and versatile. MIG welding, or Metal Inert Gas, is popular for its speed. It’s often used for thin materials. However, mastering it can be tricky for beginners.

TIG welding, on the other hand, provides high precision. It’s ideal for intricate designs and is widely used in aerospace. Spot welding is another technique. It joins metal sheets but requires skill to avoid damage. These methods have unique applications, yet they demand practice. Mistakes can happen, and reflection on them is crucial. Each project can teach valuable lessons.

Welding fabrication involves risks. Safety in this field is crucial. According to the American Welding Society, approximately 50,000 welding injuries occur annually in the U.S. This statistic emphasizes the need for adopting best practices.

Proper protective equipment is fundamental. Safety glasses, gloves, and helmets protect against sparks and harmful rays. Regular safety training is vital. Workers should understand the dangers of fumes and electric shock. Awareness can drastically reduce incidents.

Tip: Always check your gear. Ensure your equipment functions properly.

Ventilation can't be overlooked. Poor air quality can lead to serious health issues. Ensure your workspace is well-ventilated. This reduces the buildup of toxic fumes.

Tip: Use fans or respirators when necessary.

Reflection is necessary. Every project presents unique risks. Understanding these can enhance safety. Not addressing issues may lead to accidents. Make safety a priority in all welding fabrication projects.

When evaluating the cost-effectiveness of different welding methods, various factors come into play. The initial equipment investment is a significant consideration. For instance, MIG welding often has lower upfront costs compared to TIG welding. According to industry reports, the average MIG welder setup can range from $1,500 to $3,000, while TIG setups might exceed $3,500. This disparity impacts project budgets directly.

Additionally, operational costs vary among techniques. For example, MIG welding generally has higher deposition rates. This means it can complete jobs faster, potentially reducing labor costs. A study from the American Welding Society (AWS) indicates that faster processes can reduce project timelines by up to 30%. However, this speed must be matched with quality. Lower-cost methods can sometimes lead to rework, adding hidden costs.

It's crucial to consider material wastage. Some welding techniques produce less waste than others. A detailed analysis found that laser welding could minimize scrap, saving up to 20% on material costs. However, the initial setup for laser welding is more complex. This complexity can delay projects and increase training requirements. Budgeting effectively means balancing these factors against desired outcomes.

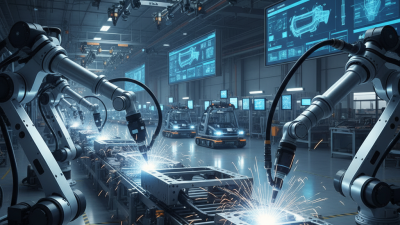

The landscape of welding fabrication is changing rapidly. Technology plays a crucial role in this transformation. Automation has introduced precision that manual methods often lack. Robotic welders now execute tasks with incredible accuracy. This minimizes human error and reduces waste significantly. However, the initial investment can be daunting for smaller shops.

Advanced software is also important in modern welding. Systems that create digital models help optimize the fabrication process. They allow welders to visualize projects before starting, reducing costly mistakes. Yet, this reliance on technology raises concerns. Skilled labor may diminish as machines take over. Workers need ongoing training to adapt to new tools. It's essential to find a balance between efficiency and craftsmanship.

Different materials require specific approaches. Steel behaves differently from aluminum under heat. Welders must understand these differences to succeed. Sometimes, technology oversimplifies complex decisions. Automation cannot replace the intuition and experience of a skilled welder. Surveillance and maintenance of automated systems are also crucial. Regular checks ensure safety and performance. Embracing technology is vital but must be approached thoughtfully.

Contact Us

Pemamek Ltd