When it comes to metal fabrication, achieving precision and efficiency is paramount. One essential tool that can significantly enhance your welding projects is the welding turntable. This equipment allows for seamless rotation of the workpiece, providing welders with better access to various angles and positions, which is crucial for creating strong, uniform welds. By utilizing a welding turntable, fabricators can reduce the time spent adjusting their materials and increase their productivity, ultimately leading to higher quality results.

In today’s fast-paced fabrication environment, selecting the right welding turntable can make a considerable difference. Whether you are a professional welder or a hobbyist, understanding the features and benefits of different turntable models is essential in ensuring you choose the best tool for your specific needs. From load capacity to speed control, each aspect plays a vital role in the overall efficiency and effectiveness of your welding operations.

Investing in a high-quality welding turntable not only enhances your welding experience but also helps in mastering metal fabrication techniques. With the right turntable, you can take your projects to the next level, ensuring precision, consistency, and optimal results every time you weld.

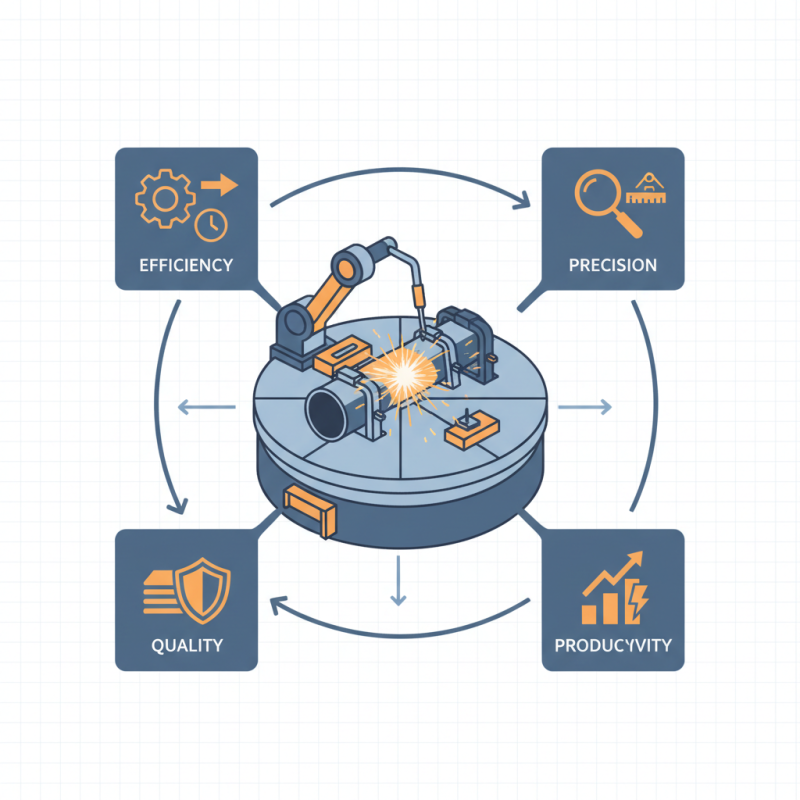

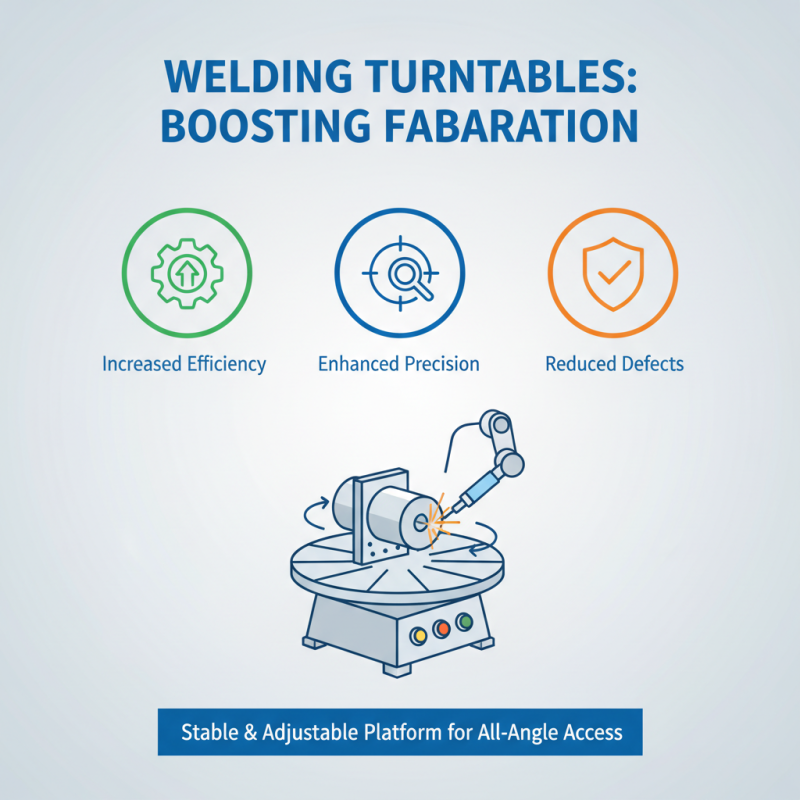

Welding turntables play a crucial role in enhancing the efficiency and precision of various metal fabrication projects. These equipment are designed to provide a stable and adjustable platform that holds workpieces securely, allowing fabricators to easily access all angles during the welding process. This accessibility not only improves the quality of welds but also reduces the risk of defects, as operators can maintain consistent positioning and control over the welding arc.

Moreover, the use of welding turntables can significantly increase productivity in a workshop setting. By rotating the workpieces rather than moving the welder, fabricators can save time and energy, allowing for faster project completion. The versatility of turntables also means they can accommodate a variety of metal sizes and shapes, making them an indispensable tool for both small-scale projects and large industrial works. As metal fabrication continues to evolve, the integration of technology and innovative equipment like welding turntables remains key to achieving superior outcomes and meeting the growing demands of the industry.

When selecting a welding turntable, several key features can significantly enhance the quality and efficiency of your metal fabrication projects. Firstly, a robust and durable construction is essential for stability during heavy welding tasks. Look for a turntable made from high-quality materials that can withstand the rigorous demands of welding, such as steel or heavy-duty aluminum. Additionally, the weight capacity of the turntable should match your project's requirements. This ensures safe handling and reduces the risk of accidents during operation.

Another important feature to consider is the adjustability of the turntable. A turntable with variable speed settings allows for greater control over the welding process, enabling you to adapt to different materials and techniques effectively. Furthermore, features such as tilting and rotation capabilities can offer enhanced accessibility to weld seams, minimizing awkward body postures that could lead to fatigue or reduced precision. Lastly, ease of setup and portability should not be overlooked; a turntable that can be easily assembled and moved will make your workspace more efficient and flexible, catering to various projects with ease.

| Feature | Description | Importance | Example Specifications |

|---|---|---|---|

| Load Capacity | The maximum weight the turntable can support. | Essential for handling various projects. | Up to 1500 lbs. |

| Rotation Speed | Adjustable speed for precision welding. | Crucial for applying even welds. | 0.1 to 1.0 RPM. |

| Dimensions | Overall size of the turntable. | Affects workspace and project size. | 36 x 36 inches. |

| Material | Quality of materials used in construction. | Durability and stability. | Steel construction. |

| Tilt and Height Adjustment | Ability to adjust tilt for various angles. | Improves access for welding. | Tilt up to 90 degrees. |

| Power Source | Type of power it runs on (e.g., electric, hydraulic). | Determines versatility and location of use. | AC power supply. |

Welding turntables are essential tools in metal fabrication, enhancing precision and efficiency in various welding applications. They come in several types, each designed for specific projects. The manual turntables allow operators to control the rotation speed and angle, making them ideal for intricate welds that require careful handling. These types of tables are often used in small workshops or by hobbyists who perform custom fabrications where detail is paramount.

On the other hand, powered turntables provide automated rotation, significantly increasing productivity in more extensive operations. These turntables can be integrated into automated production lines or utilized for large-scale projects, where consistent speed and movement are crucial. Additionally, there are tilting turntables that allow for adjusting the workpiece angle, facilitating access to hard-to-reach areas during welding. Each type of welding turntable serves its unique purpose, enhancing the versatility and capability of metal fabrication workshops, ensuring that welders can achieve optimal results in their projects.

Welding turntables have emerged as indispensable tools in metal fabrication, offering several benefits that significantly enhance the quality and efficiency of welding projects. One primary advantage is the ability to position the workpiece in the optimal orientation, allowing welders to achieve consistent and precise welds. According to industry reports, proper positioning can reduce the welding time by up to 25%, which translates into increased productivity and reduced labor costs. This efficiency allows fabricators to meet tight deadlines without compromising the quality of their work.

Additionally, welding turntables provide a stable platform that minimizes the risk of distortion and improves weld penetration. The ability to rotate and tilt the workpiece ensures that welders can access joints from various angles, leading to better fusion and strength in welds. A study by the American Welding Society indicated that using positioning devices like turntables can improve joint integrity by nearly 30%, significantly extending the lifespan of welded structures. With such clear benefits, it's no surprise that more metal fabricators are integrating turntables into their workflows, enabling them to elevate their craftsmanship and deliver superior products.

When it comes to metal fabrication, having the right tools is essential for achieving precision and quality in your projects. Welding turntables have gained popularity among both professionals and DIY enthusiasts due to their ability to improve efficiency and accuracy. These versatile tools allow users to rotate their workpieces easily, facilitating better access and control during the welding process. Selecting a high-quality welding turntable can significantly impact the results of your work, whether you're creating intricate pieces or larger structures.

For professionals, a robust and reliable turntable can make all the difference in high-volume welding jobs. Features to look for include adjustable speeds, weight capacity, and durable construction materials. Many models also offer rotating platforms that can be tilted, providing even more versatility for various welding angles. DIYers will benefit from models that are not only easy to use but also portable, allowing for flexibility in different project settings. Regardless of project size, investing in a quality welding turntable enhances precision and efficiency, ultimately leading to better results in metal fabrication.

Contact Us

Pemamek Ltd