In the ever-evolving landscape of modern fabrication, the integration of advanced technologies is paramount to ensuring efficiency and precision. One such technology that has revolutionized the welding industry is the welding manipulator. According to a report by MarketsandMarkets, the global welding equipment market is projected to reach USD 30.23 billion by 2026, with welding manipulators playing a critical role in this growth. These automated systems facilitate a range of welding processes, significantly enhancing production speed and complexity management.

Welding manipulators not only streamline operations but also improve weld quality and safety in various manufacturing sectors, from automotive to aerospace. The American Welding Society highlights that automated welding processes can increase productivity by 25% to 50% compared to manual techniques. This substantial improvement underscores the importance of adopting welding manipulators, as manufacturers seek to optimize their processes in an increasingly competitive market. As we explore the top five ways welding manipulators transform modern fabrication processes, it becomes evident that the investment in such technologies is essential for achieving operational excellence and sustaining growth in the industry.

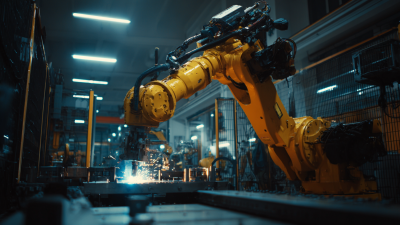

Welding manipulators play a pivotal role in enhancing fabrication efficiency by automating and optimizing the positioning of workpieces during the welding process. Traditionally, welding required significant manual effort, where welders had to adjust and reposition materials, which often led to time-consuming setups and the potential for human error.

By integrating manipulators, fabricators can achieve greater precision and consistency, ensuring that welds are performed accurately within specified tolerances.

In addition to improving precision, welding manipulators significantly increase productivity. They enable the simultaneous handling of multiple components and allow for adjustments in real-time, which reduces downtime between welding operations. This adaptability translates into quicker turnaround times for projects, allowing businesses to meet demanding production schedules more effectively. Furthermore, with the enhanced control of welding parameters provided by manipulators, fabricators can reduce material wastage and improve overall weld quality, leading to cost savings and increased customer satisfaction.

Welding manipulators have significantly transformed modern fabrication processes by enhancing production speed and reducing overall costs. These advanced tools enable precise control of welding torches, allowing for consistent and uniform welds, which minimizes defects and rework. By streamlining the positioning of workpieces, manipulators not only cut down on manual labor but also increase the efficiency of welding operations. As a result, companies can achieve higher throughput rates, addressing the growing demand for fast and reliable manufacturing.

Welding manipulators have significantly transformed modern fabrication processes by enhancing production speed and reducing overall costs. These advanced tools enable precise control of welding torches, allowing for consistent and uniform welds, which minimizes defects and rework. By streamlining the positioning of workpieces, manipulators not only cut down on manual labor but also increase the efficiency of welding operations. As a result, companies can achieve higher throughput rates, addressing the growing demand for fast and reliable manufacturing.

Statistical analyses demonstrate that the implementation of welding manipulators can lead to remarkable improvements in production metrics. For instance, operations utilizing these devices have reported a reduction in cycle times by up to 30%. Additionally, the automation of welding processes has shown to decrease labor costs significantly, providing companies with a competitive edge in pricing. These advancements highlight the crucial role of welding manipulators in modern fabrication environments, ultimately driving profitability and ensuring sustainable operational practices in an increasingly competitive market.

In recent years, the welding industry has witnessed significant advancements due to automation trends, elevating productivity and safety levels in fabrication processes. According to a report by the International Welding Institute, the integration of automated welding systems can enhance efficiency by up to 50%, reducing the overall cycle time and minimizing the possibility of human error. These technologies enable seamless operation even in complex geometries, streamlining workflows and pushing the boundaries of what is achievable in modern manufacturing.

The rise of welding manipulators has been pivotal in this automation movement, offering precise control and stability during welding procedures. A study published by the American Welding Society highlights that automated systems equipped with manipulators reduce setup times and increase the consistency of weld quality. With automated welding processes projected to grow at a compound annual growth rate (CAGR) of 8.1% through 2026, companies investing in these technologies stand to gain a competitive edge by improving production capabilities and achieving higher standards of workmanship.

Welding manipulators have become pivotal in modern fabrication processes, significantly enhancing operational efficiency and precision. Recent case studies illustrate their successful implementation across various industries, showing a marked improvement in productivity. For instance, a report by the National Institute of Standards and Technology highlighted that the adoption of automation technologies, including welding manipulators, can lead to productivity increases of up to 30% in manufacturing settings. This transformation is particularly crucial in sectors facing labor shortages and rising production costs.

Moreover, the integration of advanced technology is further underscored by recent developments in the industrial robotics field. With initiatives like the national key R&D program aiming to create a domestic platform for industrial robotics compatible with multiple brands, there is a significant shift towards localized solutions. The use of welding manipulators within this context allows manufacturers to optimize their workflows while reducing dependence on foreign software. Industry experts note that such advancements are essential for driving China’s manufacturing sector towards higher levels of autonomy and efficiency, enabling a competitive edge in the global market.

The welding industry has evolved significantly, with modern techniques revolutionizing fabrication processes. A comparative analysis reveals that traditional welding methods, such as MIG and TIG welding, often deliver results at a slower pace. According to a report by the American Welding Society, traditional processes can take up to 30% longer to complete the same tasks compared to advanced welding techniques. These traditional methods rely heavily on manual control, which can lead to inconsistencies and a higher margin of error.

In contrast, modern welding techniques, particularly those enhanced by welding manipulators, show marked improvements in efficiency and precision. Welding manipulators automate many aspects of the process, allowing for greater control over angle and speed, which enhances weld quality. A study by the International Institute of Welding indicates that fabricators utilizing robotic welding systems and manipulators have achieved productivity increases of up to 60%. The integration of these innovations not only reduces labor costs but also minimizes material waste, contributing to a more sustainable fabrication environment. As industries continue to embrace these advancements, the gap between traditional and modern welding techniques widens, underscoring the necessity for adaptation in a competitive marketplace.

| Aspect | Traditional Welding Techniques | Modern Welding Techniques |

|---|---|---|

| Welding Speed | Moderate (30-50 inches per minute) | High (80-120 inches per minute) |

| Heat Input | Higher (more distortion) | Lower (minimal distortion) |

| Operator Skill Level | High (requires extensive training) | Medium (simplified with automation) |

| Equipment Cost | Lower initial investment | Higher initial investment |

| Product Consistency | Variable | Highly consistent |

| Material Handling | Manual | Automated with manipulators |

| Flexibility | Limited | Highly flexible for various jobs |

Contact Us

Pemamek Ltd