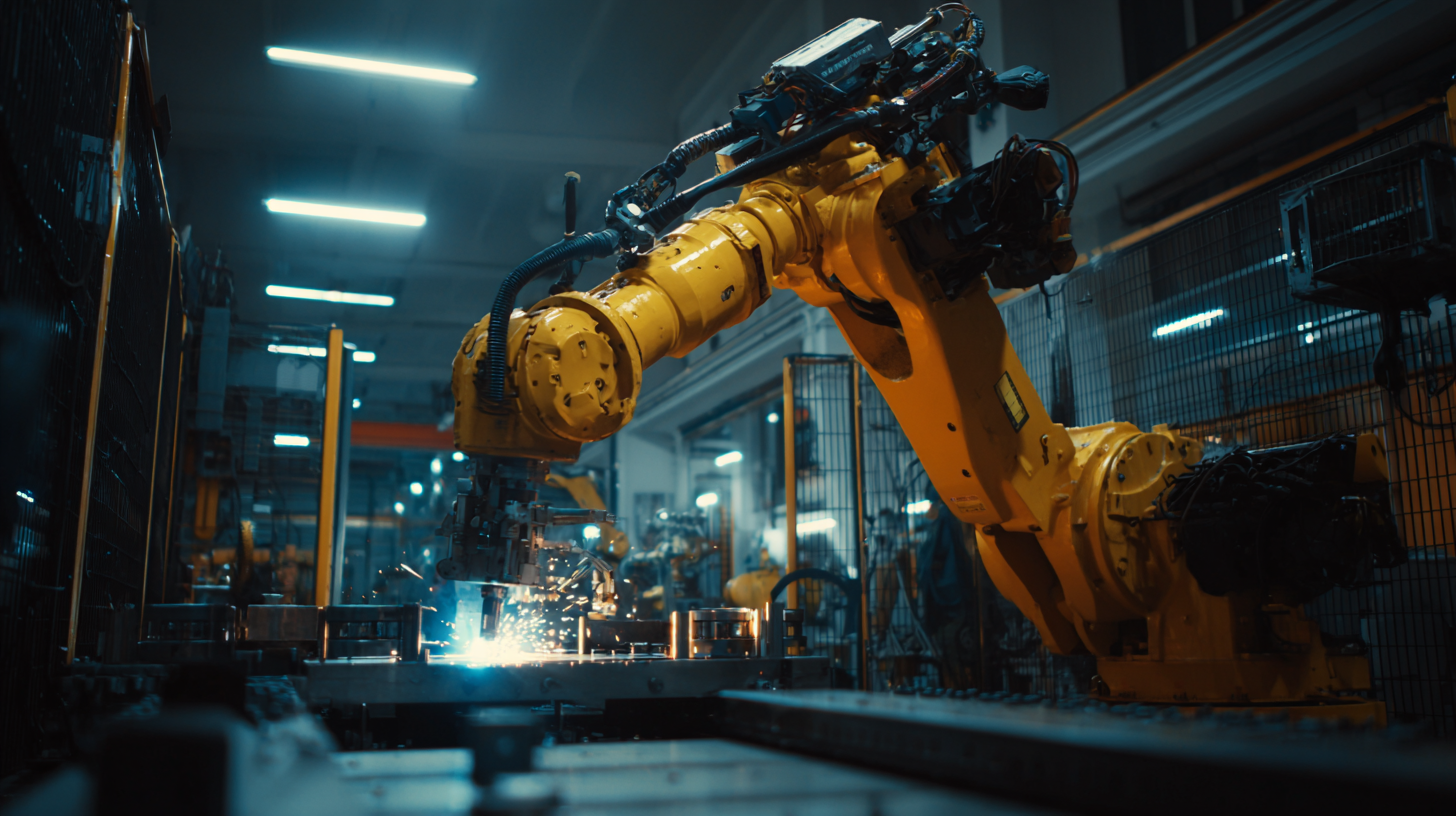

In the ever-evolving landscape of manufacturing, the advent of the automated welding machine has marked a significant turning point in achieving precision and efficiency. These cutting-edge machines are revolutionizing how welding processes are executed, seamlessly integrating advanced technology to enhance productivity while ensuring high-quality outcomes in various applications. As manufacturers face increasing demands for speed and accuracy, the transition towards automated solutions becomes not just beneficial but essential. This guide will delve into the key advantages of adopting automated welding machines, exploring innovative techniques that can streamline operations and reduce costs, while also shedding light on best practices for implementation. Join us as we navigate the future of welding, where innovation meets practicality, driving the manufacturing industry towards new heights of excellence.

Automated welding machines are transforming the landscape of modern manufacturing by significantly enhancing

precision and efficiency. According to a report by the International Federation of Robotics, the global market for industrial robots, including automated welding systems, is projected to reach $73 billion by 2025, reflecting an annual growth rate of 17%. This extraordinary growth underscores the increasing reliance on these technologies to meet the rising demands for high-quality production.

Automated welding machines are transforming the landscape of modern manufacturing by significantly enhancing

precision and efficiency. According to a report by the International Federation of Robotics, the global market for industrial robots, including automated welding systems, is projected to reach $73 billion by 2025, reflecting an annual growth rate of 17%. This extraordinary growth underscores the increasing reliance on these technologies to meet the rising demands for high-quality production.

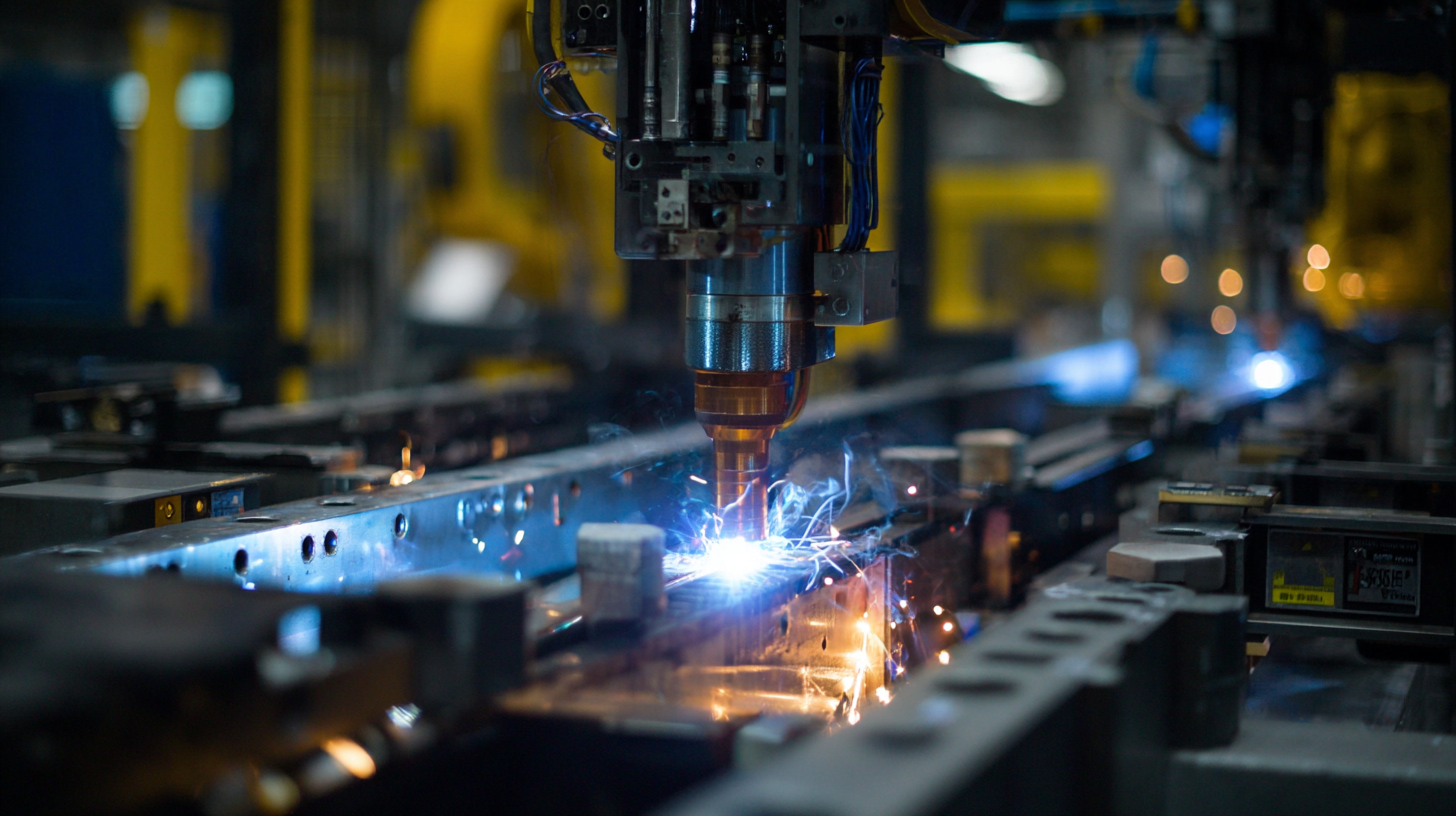

One of the key advantages of automated welding machines is their remarkable accuracy. Studies indicate that automated processes can achieve weld accuracy rates above 95%, compared to the 70-80% rates typically seen in manual welding operations. This high level of precision not only minimizes defects but also reduces material waste, leading to cost savings that manufacturers can reinvest into their operations. Furthermore, with the ability to operate continuously without fatigue or breaks, automated welding systems increase overall productivity, enabling manufacturers to significantly shorten production timelines and respond more swiftly to market fluctuations. As industries continue to evolve, the integration of automated welding technology presents a compelling case for manufacturers aiming to innovate and improve operational efficiencies.

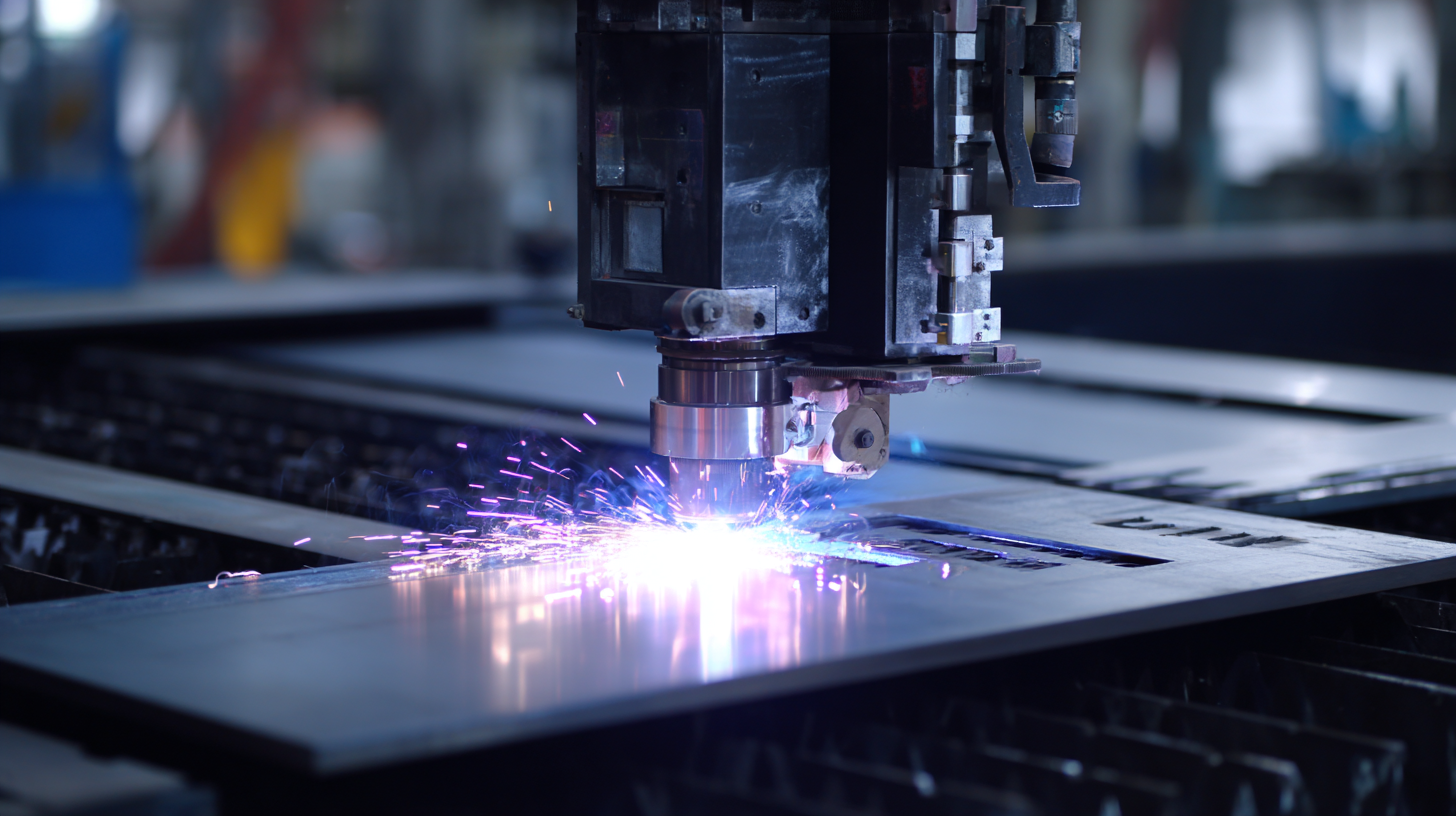

The global robotic welding market is on an impressive growth trajectory, projected to increase from $8.1 billion in 2025 to $20.16 billion by 2032, reflecting a compound annual growth rate (CAGR) of 13.9%. This surge highlights the industry's shift towards automation as manufacturers seek enhanced precision and efficiency in their processes. Automated welding machines are becoming essential in various sectors, including automotive, aerospace, and construction, where consistent quality and speed are paramount.

In addition to robotic welding, the market for smart welding monitoring solutions is also expanding, with expectations to reach $2.3 billion by 2035, growing at a CAGR of 6.3%. This advancement in technology enables real-time monitoring of the welding process, significantly improving the quality of welds and reducing the probability of defects. Furthermore, the global welding consumables market is anticipated to grow from $20.3 billion in 2025, showcasing a steady growth rate of 5.6%. These statistics collectively illustrate a robust and rapidly evolving landscape in the welding industry, driven by innovations in automation and monitoring technologies.

| Year | Global Market Size (in Billion USD) | Growth Rate (%) | Automated Welding Adoption (%) | Industry Application Areas (%) |

|---|---|---|---|---|

| 2020 | 4.5 | 8.5 | 35 | 60 |

| 2021 | 5.0 | 11.1 | 40 | 62 |

| 2022 | 5.6 | 12.0 | 45 | 65 |

| 2023 | 6.2 | 10.7 | 50 | 68 |

| 2024 | 7.0 | 12.9 | 55 | 70 |

The shift from traditional to automated welding processes is not merely an incremental change; it signifies a transformative leap in manufacturing efficiency. According to recent market analyses, the global welding robotics market is expected to reach approximately $19.9 billion by 2032, with a CAGR of 10%. This growth underscores the pivotal role that automation plays in driving precision and reducing operational costs within manufacturing facilities.

Automated welding machines streamline production processes, significantly reducing the time typically associated with manual welding. While traditional methods may involve extensive labor and time-consuming setups, automated solutions can accomplish tasks with unparalleled speed and consistency. For instance, AI-driven frameworks such as Physics-informed Hybrid Optimization showcase how technology can enhance robotic welding's efficiency—transforming industrial fabrication by integrating data-driven insights for optimal performance.

Tips: To maximize the benefits of automated welding, consider investing in training for your workforce to effectively manage and maintain these advanced machines. Furthermore, exploring collaborative robots can further enhance your production lines, allowing for adaptive automation that works seamlessly alongside human operators. This combination not only boosts efficiency but also fosters a safer working environment.

The integration of AI and machine learning into automated welding machines is revolutionizing the manufacturing industry by dramatically enhancing the precision of welds. These advanced technologies enable machines to analyze vast amounts of data in real-time, leading to clearer insights and optimized welding parameters. For instance, algorithms can adapt the welding speed, heat input, and even the angles of the welding torches to ensure that every joint meets the desired specifications. This dynamic adjustment not only results in stronger and more reliable welds but also reduces waste and rework, significantly improving efficiency.

**Tip:** To maximize the benefits of AI in your welding operations, consider investing in training for your team. Familiarity with machine learning concepts can empower personnel to leverage these technologies effectively, ensuring improved outcomes.

Moreover, machine learning algorithms can predict potential defects by learning from past welding projects. By identifying patterns that lead to failures, manufacturers can preemptively adjust their processes to avoid such issues. The continuous learning capabilities of these systems mean that over time, the precision of welds will only improve as they adapt to new data and conditions in the manufacturing environment.

**Tip:** Regularly update your welding machines and algorithm software to stay at the forefront of technological advancements, ensuring that your operations remain efficient and precise.

This chart illustrates the improvements in welding precision and efficiency due to the integration of AI and machine learning in automated welding machines.

The automated welding machine market is poised for significant growth, with projections indicating a value of $14.93 billion in 2024, increasing to $15.96 billion in 2025, and reaching an impressive $272.26 billion by 2033. This consistent upward trend underscores the industry's transition towards greater precision and efficiency in manufacturing processes, driven by technological advancements and the growing demand for automation across various sectors.

Furthermore, the arc welding robot market is expected to show robust expansion, with its valuation estimated at $409.43 million in 2025, anticipated to grow to $541.37 million by 2033. As industries like construction and automotive increasingly integrate automated solutions, the types of welding technologies—ranging from resistance welding to arc welding—will play a pivotal role in shaping market dynamics. The strategic adoption of these advanced welding machines not only enhances manufacturing capabilities but also aligns with future trends emphasizing innovation and sustainability within the production landscape.

Contact Us

Pemamek Ltd