In the realm of modern manufacturing, the advent of welding automation has brought about transformative advancements that propel operational efficiency and product quality to unprecedented levels. According to a report by *Welding Journal*, automated welding processes can enhance production rates by as much as 30%, significantly reducing labor costs and minimizing human error. As industries strive to meet the demands of an increasingly competitive market, the integration of welding automation is no longer a luxury but a crucial strategy for achieving manufacturing excellence.

Moreover, the global welding equipment market is projected to reach USD 20 billion by 2025, driven by the integration of smart technologies and automation practices. This shift not only emphasizes the importance of welding automation in improving productivity but also highlights its role in fostering safety and reducing workplace injuries. As manufacturers aim to optimize their operations, it is essential to recognize the top benefits that welding automation brings, ranging from enhanced precision to scalable production capabilities. Embracing these advancements sets the foundation for sustainable growth and innovation in the manufacturing landscape.

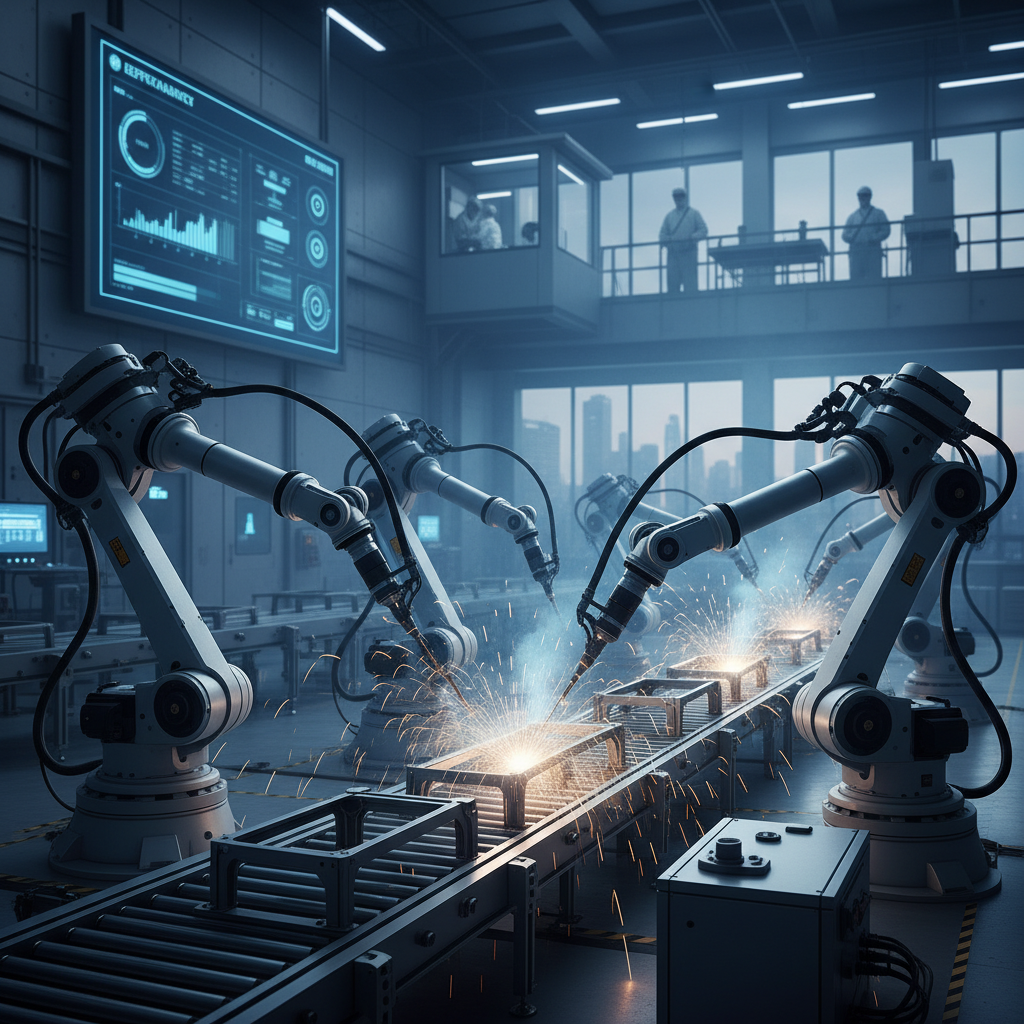

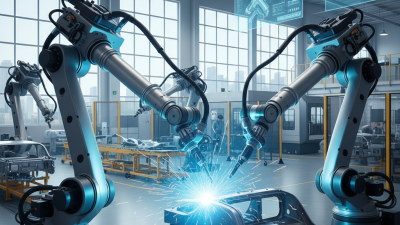

The integration of welding automation in modern manufacturing significantly elevates the precision and consistency of welding processes. Automated systems utilize high-tech robotics equipped with advanced sensors and software that meticulously control every aspect of the welding operation. This technology reduces human error, ensuring that each weld is executed with the same accuracy and quality, regardless of the production volume or complexity of the component. For manufacturers, this means fewer defects and reworks, ultimately enhancing product reliability.

Furthermore, automated welding solutions provide a controlled environment that maintains optimal parameters throughout the entire weld cycle. This consistency not only improves the structural integrity of welded joints but also optimizes material usage, as the precise application of heat and filler materials reduces wastage. By leveraging automation, companies can achieve a higher degree of predictability in their manufacturing processes, allowing for better planning and resource management. The focus on precision and consistency is not merely a benefit but a foundation for achieving excellence in manufacturing operations.

Welding automation has become a pivotal component in modern manufacturing, primarily driven by the need for increased production speed and efficiency. By integrating automated welding systems into their operations, manufacturers can significantly reduce cycle times, allowing for a greater volume of products to be produced within the same timeframe. Automated systems can perform repetitive welding tasks consistently and quickly, ensuring that each weld meets the predefined quality standards without the variability that can occur with manual labor.

Moreover, the efficiency gained through automation not only enhances production rates but also optimizes resource utilization. Automation minimizes waste by providing precise control over the welding process, reducing the chances of defects and the need for rework. As a result, manufacturers can allocate their resources more effectively, directing labor and materials toward higher-value tasks. This shift ultimately leads to better profit margins and a more competitive edge in the marketplace, demonstrating how welding automation serves as a catalyst for modern manufacturing excellence.

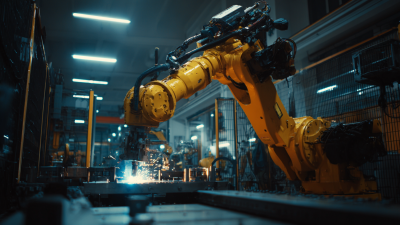

Welding automation is transforming modern manufacturing by significantly enhancing cost savings and resource optimization. As companies like Merck implement cost-cutting plans to redirect resources toward innovation, the integration of automated welding processes emerges as a crucial strategy. Automated welding systems reduce labor costs, minimize material waste, and increase production rates by ensuring precision and consistency. These innovations allow manufacturers to reallocate savings toward the development of new products and technologies, ultimately driving growth and competitiveness in the market.

Furthermore, the growing adoption of artificial intelligence in manufacturing supports these automation efforts by enhancing operational efficiency. Predictive maintenance powered by AI minimizes unplanned downtimes, ensuring that welding machinery operates at peak performance. This not only leads to significant cost reductions but also enhances the overall quality of the manufacturing outputs. By embracing welding automation, businesses can achieve a streamlined production process, optimize the use of resources, and align their operational strategies with sustainability goals, ultimately redefining excellence in the manufacturing sector.

Welding automation significantly enhances worker safety in manufacturing environments. Traditional welding processes often expose workers to hazardous conditions, including harmful fumes, intense heat, and the risk of accidents from manual handling. By implementing automated welding systems, manufacturers can minimize direct exposure to these dangers. Automated machines take over the physically demanding and hazardous tasks, allowing workers to operate from a safe distance, thereby reducing the likelihood of injury and exposure to harmful substances.

In addition to safety improvements, welding automation also contributes to better ergonomic conditions for employees. Manual welding can lead to musculoskeletal disorders due to repetitive movements and awkward postures. Automation alleviates these issues by handling the bulk of the strenuous tasks, allowing workers to focus on overseeing operations rather than performing physically taxing work. This shift not only promotes a healthier work environment but also enhances overall productivity, as employees can concentrate on strategic tasks that require their expertise rather than exhausting manual labor.

In today's fast-evolving manufacturing landscape, the need for flexibility and scalability has never been more critical.

Welding automation significantly enhances these aspects, allowing manufacturers to swiftly adapt to changing market demands.

With the global data warehouse as a service market projected to grow from $9.79 billion in 2025 to $39.58 billion by 2032,

it is evident that businesses are increasingly recognizing the value of scalable solutions.

This inclination mirrors the broader trend seen across various technology sectors, such as the hybrid cloud market, which is estimated to surpass USD 577.6 billion by 2033,

driven by the increasing necessity for robust and adaptable AI infrastructure.

Moreover, Business Process Outsourcing (BPO) has also emerged as a strategic tool, enabling organizations to remain competitive in rapidly changing global markets.

By leveraging BPO, companies can achieve enhanced operational flexibility and responsiveness, thus positioning themselves favorably in the face of uncertainty.

The strong correlation between flexibility and business resilience is clear, with market demands accelerating the push for innovative solutions that combine both scalability and efficiency.

As industries transition towards automated and modular systems, the shift not only bolsters manufacturing capabilities but also aligns with the overall trends of technological advancement across multiple sectors.

Contact Us

Pemamek Ltd